日本佑能UNION 2刃UT涂层 CSEB系列球刀

品牌:UNION(佑能)

型号:G5ACC1CAC0F462

¥待询价(提交订单10分钟内获取专属报价单)

| 加工材料 | |||||||||||||||

| 碳素钢 S45C S55C | 合金钢 SK/SCM SUS | 预硬钢 NAK HPM | 淬火钢 | 铸铁 | 铝合金 | 石墨 | 铜 | 树脂 | 玻璃纤维 树脂 | 钛合金 | 高温合金 | 超硬合金 | 硬脆材料 | ||

| ~55HRC | ~60HRC | ~70HRC | |||||||||||||

| ○ | ○ | ◎ | ◎ | ◎ | ◎ | ○ | ○ | ○ | ○ | ||||||

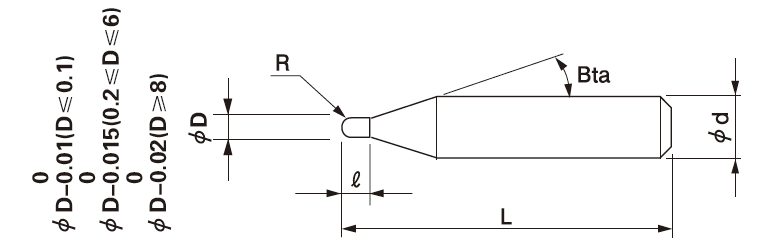

| 球半径 | 直径公差 | R精度 | 螺旋角 | 刃数 |

| R0.03~R0.05 | 0/-0.01 |

|

| 2刃 * |

| R0.1~R3 | 0/-0.015 |

|

| |

| R4~R6 | 0/-0.02 |

|

| 型号 | 球半径 R | 刃长 R | 柄锥角度 Bta | 全长 L | 柄径 φd |

| HSB20006-0006 | R0.03 | 0.06 | 11° | 50 | 4 |

| HSB20008-0008 | R0.04 | 0.08 | 11° | 50 | 4 |

| HSB1001-0020-6 | R0.05 | 0.2 | 11° | 50 | 6 |

| HSB2001-0010 | R0.05 | 0.1 | 11° | 50 | 4 |

| HSB2002-0020-6 | R0.1 | 0.2 | 16° | 50 | 6 |

| HSB2002-0030 | 0.3 | 50 | 4 | ||

| HSB2003-0030 | R0.15 | 0.3 | 16° | 50 | 4 |

| HSB2003-0030-6 | 0.3 | 50 | 6 | ||

| HSB2003-0045 | 0.45 | 50 | 4 | ||

| HSB2004-0040 | R0.2 | 0.4 | 16° | 50 | 4 |

| HSB2004-0040-6 | 0.4 | 50 | 6 | ||

| HSB2004-0060 | 0.6 | 50 | 4 | ||

| HSB2005-0050 | R0.25 | 0.5 | 16° | 50 | 4 |

| HSB2005-0050-6 | 0.5 | 50 | 6 | ||

| HSB2005-0075 | 0.75 | 50 | 4 |

| HSB2006-0060 | R0.3 | 0.6 | 16° | 50 | 4 |

| HSB2006-0060-6 | 0.6 | 50 | 6 | ||

| HSB2006-0090 | 0.9 | 50 | 4 | ||

| HSB2007-0100 | R0.35 | 1 | 16° | 50 | 4 |

| HSB2008-0080 | R0.4 | 0.8 | 16° | 50 | 4 |

| HSB2008-0080-6 | 0.8 | 50 | 6 | ||

| HSB2008-0120 | 1.2 | 50 | 4 | ||

| HSB2009-0130 | R0.45 | 1.3 | 16° | 50 | 4 |

| HSB2010-0100 | R0.5 | 1 | 16° | 50 | 4 |

| HSB2010-0100-6 | 1 | 50 | 6 | ||

| HSB2010-0150 | 1.5 | 50 | 4 | ||

| HSB2010-0250 | 2.5 | 50 | 4 | ||

| HSB2011-0160 | R0.55 | 1.6 | 16° | 50 | 4 |

| HSB2012-0180 | R0.6 | 1.8 | 16° | 50 | 4 |

| HSB2013-0190 | R0.65 | 1.9 | 16° | 50 | 4 |

| HSB2014-0210 | R0.7 | 2.1 | 16° | 50 | 4 |

| HSB2015-0150 | R0.75 | 1.5 | 16° | 50 | 4 |

| HSB2015-0150-6 | 1.5 | 50 | 6 | ||

| HSB2015-0200 | 2 | 50 | 4 | ||

| HSB2015-0225 | 2.25 | 50 | 4 | ||

| HSB2015-0400 | 4 | 50 | 4 | ||

| HSB2016-0240 | R0.8 | 2.4 | 16° | 50 | 4 |

| HSB2017-0250 | R0.85 | 2.5 | 16° | 50 | 4 |

| HSB2018-0270 | R0.9 | 2.7 | 16° | 50 | 4 |

| HSB2019-0280 | R0.95 | 2.8 | 16° | 50 | 4 |

| HSB2020-0200 | R1 | 2 | 16° | 50 | 4 |

| HSB2020-0200-6 | 2 | 60 | 6 | ||

| HSB2020-0300 | 3 | 50 | 4 | ||

| HSB2020-0600 | 6 | 60 | 4 | ||

| HSB2025-0250 | R1.25 | 2.5 | 16° | 50 | 4 |

| HSB2025-0250-6 | 2.5 | 60 | 6 | ||

| HSB2025-0375 | 3.75 | 50 | 4 | ||

| HSB2025-0600 | 6 | 60 | 4 | ||

| HSB2030-0300 | R1.5 | 3 | 16° | 50 | 6 |

| HSB2030-0450 | 4.5 | 70 | 6 | ||

| HSB2030-0800 | 8 | 70 | 6 | ||

| HSB2040-0400 | R2 | 4 | 16° | 50 | 6 |

| HSB2040-0600 | 6 | 70 | 6 | ||

| HSB2040-0800 | 8 | 70 | 6 | ||

| HSB2050-0500 | R2.5 | 5 | 16° | 50 | 6 |

| HSB2050-0750 | 7.5 | 80 | 6 | ||

| HSB2050-0800 | 8 | 80 | 6 | ||

| HSB2050-1200 | 12 | 80 | 6 | ||

| HSB2060-0600 | R3 | 6 | — | 50 | 6 |

| HSB2060-0900 | 9 | 80 | 6 | ||

| HSB2060-1200 | 12 | 80 | 6 | ||

| HSB2080-0800 | R4 | 8 | — | 60 | 8 |

| HSB2080-1200 | 12 | 90 | 8 | ||

| HSB2080-1400 | 14 | 90 | 8 | ||

| HSB2100-1000 | R5 | 10 | — | 70 | 10 |

| HSB2100-1500 | 15 | 100 | 10 | ||

| HSB2100-1800 | 18 | 100 | 10 | ||

| HSB2120-1200 | R6 | 12 | — | 75 | 12 |

| HSB2120-1800 | 18 | 110 | 12 | ||

| HSB2120-2200 | 22 | 110 | 12 |

| 加工材料 | 预硬钢/淬火钢 NAK/STAVAX(~55HRC) | 淬火钢 SKD11(55~62HRC) | 淬火钢 HAP10(62~66HRC) | 淬火钢 HAP72(66~70HRC) | ||||||||||||||

| 型号 | 球半径 (mm) | 刃长 (mm) | 转速 (min-1) | 进给 (mm/min) | ap (mm) | ae (mm) | 转速 (min-1) | 进给 (mm/min) | ap (mm) | ae (mm) | 转速 (min-1) | 进给 (mm/min) | ap (mm) | ae (mm) | 转速 (min-1) | 进给 (mm/min) | ap (mm) | ae (mm) |

| 20006-0006 | R0.03 | 0.06 | 30,000 | 100 | 0.002以下 | 0.02 | — | — | — | — | — | — | — | — | — | — | — | — |

| 20008-0008 | R0.04 | 0.08 | 30,000 | 130 | 0.003以下 | 0.03 | — | — | — | — | — | — | — | — | — | — | — | — |

| 1001-0020-6 | R0.05 | 0.2 | 30,000 | 30 | 0.002以下 | 0.02 | — | — | — | — | — | — | — | — | — | — | — | — |

| 2001-0010 | 0.1 | 30,000 | 200 | 0.004以下 | 0.04 | — | — | — | — | — | — | — | — | — | — | — | — | |

| 2002-0020-6 | R0.1 | 0.2 | 60,000 | 200 | 0.003 | 0.005 | 60,000 | 200 | 0.002 | 0.003 | 60,000 | 130 | 0.002 | 0.003 | 45,000 | 65 | 0.002 | 0.003 |

| 2002-0030 | 0.3 | 60,000 | 200 | 0.003 | 0.005 | 60,000 | 200 | 0.002 | 0.003 | 60,000 | 130 | 0.002 | 0.003 | 45,000 | 65 | 0.002 | 0.003 | |

| 2003-0030(-6) | R0.15 | 0.3 | 60,000 | 350 | 0.006 | 0.008 | 45,000 | 310 | 0.004 | 0.007 | 43,500 | 180 | 0.003 | 0.005 | 32,500 | 90 | 0.003 | 0.005 |

| 2003-0045 | 0.45 | 60,000 | 350 | 0.006 | 0.008 | 45,000 | 310 | 0.004 | 0.007 | 43,500 | 180 | 0.003 | 0.005 | 32,500 | 90 | 0.003 | 0.005 | |

| 2004-0040(-6) | R0.2 | 0.4 | 50,000 | 500 | 0.01 | 0.02 | 37,500 | 420 | 0.007 | 0.012 | 35,000 | 240 | 0.005 | 0.008 | 26,250 | 120 | 0.005 | 0.008 |

| 2004-0060 | 0.6 | 50,000 | 500 | 0.01 | 0.02 | 37,500 | 420 | 0.007 | 0.012 | 35,000 | 240 | 0.005 | 0.008 | 26,250 | 120 | 0.005 | 0.008 | |

| 2005-0050(-6) | R0.25 | 0.5 | 44,000 | 650 | 0.015 | 0.04 | 33,000 | 530 | 0.01 | 0.02 | 30,000 | 300 | 0.007 | 0.01 | 22,500 | 150 | 0.007 | 0.01 |

| 2005-0075 | 0.75 | 44,000 | 650 | 0.015 | 0.04 | 33,000 | 530 | 0.01 | 0.02 | 30,000 | 300 | 0.007 | 0.01 | 22,500 | 150 | 0.007 | 0.01 | |

| 2006-0060(-6) | R0.3 | 0.6 | 40,000 | 1,100 | 0.03 | 0.13 | 30,000 | 1,200 | 0.02 | 0.1 | 26,500 | 800 | 0.01 | 0.075 | 20,000 | 400 | 0.01 | 0.075 |

| 2006-0090 | 0.9 | 40,000 | 1,100 | 0.03 | 0.13 | 30,000 | 1,200 | 0.02 | 0.1 | 26,500 | 800 | 0.01 | 0.075 | 20,000 | 400 | 0.01 | 0.075 | |

| 2007-0100 | R0.35 | 1 | 37,000 | 1,350 | 0.045 | 0.17 | 28,500 | 1,400 | 0.03 | 0.135 | 25,000 | 900 | 0.015 | 0.1 | 18,750 | 450 | 0.015 | 0.1 |

| 2008-0080(-6) | R0.4 | 0.8 | 35,000 | 1,600 | 0.06 | 0.21 | 27,000 | 1,600 | 0.04 | 0.17 | 23,500 | 1,000 | 0.02 | 0.12 | 17,500 | 500 | 0.02 | 0.12 |

| 2008-0120 | 1.2 | 35,000 | 1,600 | 0.06 | 0.21 | 27,000 | 1,600 | 0.04 | 0.17 | 23,500 | 1,000 | 0.02 | 0.12 | 17,500 | 500 | 0.02 | 0.12 | |

| 2009-0130 | R0.45 | 1.3 | 32,500 | 1,650 | 0.1 | 0.28 | 25,500 | 1,800 | 0.055 | 0.21 | 22,000 | 1,300 | 0.025 | 0.14 | 16,500 | 650 | 0.025 | 0.14 |

| 2010-0100(-6) | R0.5 | 1 | 30,000 | 1,750 | 0.2 | 0.4 | 24,000 | 2,000 | 0.1 | 0.3 | 21,000 | 1,750 | 0.05 | 0.2 | 16,000 | 875 | 0.05 | 0.2 |

| 2010-0150 | 1.5 | 30,000 | 1,750 | 0.2 | 0.4 | 24,000 | 2,000 | 0.1 | 0.3 | 21,000 | 1,750 | 0.05 | 0.2 | 16,000 | 875 | 0.05 | 0.2 | |

| 2010-0250 | 2.5 | 30,000 | 1,750 | 0.1 | 0.3 | 24,000 | 2,000 | 0.05 | 0.2 | 21,000 | 1,750 | 0.03 | 0.17 | 16,000 | 875 | 0.03 | 0.17 | |

| 2011-0160 | R0.55 | 1.6 | 30,000 | 1,900 | 0.21 | 0.43 | 22,000 | 2,000 | 0.105 | 0.32 | 19,000 | 1,750 | 0.05 | 0.22 | 14,250 | 875 | 0.05 | 0.22 |

| 2012-0180 | R0.6 | 1.8 | 30,000 | 2,000 | 0.22 | 0.46 | 20,500 | 2,000 | 0.11 | 0.34 | 17,800 | 1,750 | 0.05 | 0.23 | 13,350 | 875 | 0.05 | 0.23 |

| 2013-0190 | R0.65 | 1.9 | 30,000 | 2,150 | 0.23 | 0.49 | 19,000 | 2,000 | 0.115 | 0.36 | 16,600 | 1,750 | 0.05 | 0.24 | 12,450 | 875 | 0.05 | 0.24 |

| 2014-0210 | R0.7 | 2.1 | 30,000 | 2,300 | 0.24 | 0.52 | 18,000 | 2,000 | 0.12 | 0.39 | 15,700 | 1,750 | 0.055 | 0.27 | 11,800 | 875 | 0.055 | 0.27 |

| 2015-0150(-6) | R0.75 | 1.5 | 30,000 | 2,450 | 0.25 | 0.55 | 17,000 | 2,000 | 0.12 | 0.4 | 15,000 | 1,750 | 0.06 | 0.29 | 11,250 | 875 | 0.06 | 0.29 |

| 2015-0200 | 2 | 30,000 | 2,450 | 0.25 | 0.55 | 17,000 | 2,000 | 0.12 | 0.4 | 15,000 | 1,750 | 0.06 | 0.29 | 11,250 | 875 | 0.06 | 0.29 | |

| 2015-0225 | 2.25 | 30,000 | 2,450 | 0.25 | 0.55 | 17,000 | 2,000 | 0.12 | 0.4 | 15,000 | 1,750 | 0.06 | 0.29 | 11,250 | 875 | 0.06 | 0.29 | |

| 2015-0400 | 4 | 30,000 | 2,450 | 0.15 | 0.45 | 17,000 | 2,000 | 0.07 | 0.31 | 15,000 | 1,750 | 0.04 | 0.24 | 11,250 | 875 | 0.04 | 0.24 | |

| 2016-0240 | R0.8 | 2.4 | 30,000 | 2,550 | 0.25 | 0.58 | 16,200 | 2,000 | 0.13 | 0.43 | 14,200 | 1,750 | 0.06 | 0.3 | 10,650 | 875 | 0.06 | 0.3 |

| 2017-0250 | R0.85 | 2.5 | 30,000 | 2,600 | 0.26 | 0.61 | 15,500 | 2,000 | 0.135 | 0.46 | 13,500 | 1,750 | 0.065 | 0.32 | 10,100 | 875 | 0.065 | 0.32 |

| 2018-0270 | R0.9 | 2.7 | 30,000 | 2,700 | 0.28 | 0.65 | 15,000 | 2,000 | 0.14 | 0.48 | 13,000 | 1,750 | 0.07 | 0.34 | 9,750 | 875 | 0.07 | 0.34 |

| 2019-0280 | R0.95 | 2.8 | 29,000 | 2,800 | 0.3 | 0.69 | 14,500 | 2,000 | 0.145 | 0.49 | 12,600 | 1,750 | 0.075 | 0.36 | 9,450 | 875 | 0.075 | 0.36 |

| 2020-0200(-6) | R1 | 2 | 28,000 | 2,900 | 0.3 | 0.7 | 14,000 | 2,100 | 0.15 | 0.5 | 12,250 | 1,800 | 0.08 | 0.35 | 9,200 | 900 | 0.08 | 0.35 |

| 2020-0300 | 3 | 28,000 | 2,900 | 0.3 | 0.7 | 14,000 | 2,100 | 0.15 | 0.5 | 12,250 | 1,800 | 0.08 | 0.35 | 9,200 | 900 | 0.08 | 0.35 | |

| 2020-0600 | 6 | 28,000 | 2,900 | 0.2 | 0.6 | 14,000 | 2,100 | 0.1 | 0.4 | 12,250 | 1,800 | 0.06 | 0.3 | 9,200 | 900 | 0.06 | 0.3 | |

| 2025-0250(-6) | R1.25 | 2.5 | 24,500 | 2,950 | 0.35 | 0.85 | 12,250 | 2,150 | 0.17 | 0.6 | 10,700 | 1,850 | 0.1 | 0.45 | 8,050 | 925 | 0.1 | 0.45 |

| 2025-0375 | 3.75 | 24,500 | 2,950 | 0.35 | 0.85 | 12,250 | 2,150 | 0.17 | 0.6 | 10,700 | 1,850 | 0.1 | 0.45 | 8,050 | 925 | 0.1 | 0.45 | |

| 2025-0600 | 6 | 24,500 | 2,950 | 0.26 | 0.75 | 12,250 | 2,150 | 0.125 | 0.5 | 10,700 | 1,850 | 0.08 | 0.4 | 8,050 | 925 | 0.08 | 0.4 | |

| 2030-0300 | R1.5 | 3 | 21,000 | 3,000 | 0.4 | 1 | 10,500 | 2,200 | 0.2 | 0.7 | 9,200 | 1,900 | 0.12 | 0.55 | 6,900 | 950 | 0.12 | 0.55 |

| 2030-0450 | 4.5 | 21,000 | 3,000 | 0.4 | 1 | 10,500 | 2,200 | 0.2 | 0.7 | 9,200 | 1,900 | 0.12 | 0.55 | 6,900 | 950 | 0.12 | 0.55 | |

| 2030-0800 | 8 | 21,000 | 3,000 | 0.3 | 0.9 | 10,500 | 2,200 | 0.15 | 0.65 | 9,200 | 1,900 | 0.1 | 0.5 | 6,900 | 950 | 0.1 | 0.5 | |

| 2040-0400 | R2 | 4 | 18,000 | 3,200 | 0.5 | 1.3 | 9,000 | 2,300 | 0.25 | 0.95 | 7,900 | 2,000 | 0.15 | 0.75 | 5,900 | 1,000 | 0.15 | 0.75 |

| 2040-0600 | 6 | 18,000 | 3,200 | 0.5 | 1.3 | 9,000 | 2,300 | 0.25 | 0.95 | 7,900 | 2,000 | 0.15 | 0.75 | 5,900 | 1,000 | 0.15 | 0.75 | |

| 2040-0800 | 8 | 18,000 | 3,200 | 0.5 | 1.3 | 9,000 | 2,300 | 0.25 | 0.95 | 7,900 | 2,000 | 0.15 | 0.75 | 5,900 | 1,000 | 0.15 | 0.75 | |

| 2050-0500 | R2.5 | 5 | 15,600 | 3,500 | 0.5 | 1.5 | 7,800 | 2,500 | 0.25 | 1.05 | 6,800 | 2,100 | 0.15 | 0.85 | 5,100 | 1,050 | 0.15 | 0.85 |

| 2050-0750 | 7.5 | 15,600 | 3,500 | 0.5 | 1.5 | 7,800 | 2,500 | 0.25 | 1.05 | 6,800 | 2,100 | 0.15 | 0.85 | 5,100 | 1,050 | 0.15 | 0.85 | |

| 2050-0800 | 8 | 15,600 | 3,500 | 0.5 | 1.5 | 7,800 | 2,500 | 0.25 | 1.05 | 6,800 | 2,100 | 0.15 | 0.85 | 5,100 | 1,050 | 0.15 | 0.85 | |

| 2050-1200 | 12 | 15,600 | 3,500 | 0.5 | 1.5 | 7,800 | 2,500 | 0.25 | 1.05 | 6,800 | 2,100 | 0.15 | 0.85 | 5,100 | 1,050 | 0.15 | 0.85 | |

| 加工材料 | 预硬钢/淬火钢 NAK/STAVAX(~55HRC) | 淬火钢 SKD11(55~62HRC) | 淬火钢 HAP10(62~66HRC) | 淬火钢 HAP72(66~70HRC) | ||||||||||||||

| 型号 | 球半径 (mm) | 刃长 (mm) | 转速 (min-1) | 进给 (mm/min) | ap (mm) | ae (mm) | 转速 (min-1) | 进给 (mm/min) | ap (mm) | ae (mm) | 转速 (min-1) | 进给 (mm/min) | ap (mm) | ae (mm) | 转速 (min-1) | 进给 (mm/min) | ap (mm) | ae (mm) |

| 2060-0600 | R3 | 6 | 13,000 | 3,500 | 0.6 | 1.8 | 6,500 | 2,500 | 0.3 | 1.3 | 5,700 | 2,200 | 0.2 | 1 | 4,300 | 1,100 | 0.2 | 1 |

| 2060-0900 | 9 | 13,000 | 3,500 | 0.6 | 1.8 | 6,500 | 2,500 | 0.3 | 1.3 | 5,700 | 2,200 | 0.2 | 1 | 4,300 | 1,100 | 0.2 | 1 | |

| 2060-1200 | 12 | 13,000 | 3,500 | 0.6 | 1.8 | 6,500 | 2,500 | 0.3 | 1.3 | 5,700 | 2,200 | 0.2 | 1 | 4,300 | 1,100 | 0.2 | 1 | |

| 2080-0800 | R4 | 8 | 9,500 | 3,000 | 0.7 | 2.1 | 5,200 | 2,200 | 0.4 | 1.7 | 4,500 | 1,900 | 0.25 | 1.35 | 3,400 | 950 | 0.25 | 1.35 |

| 2080-1200 | 12 | 9,500 | 3,000 | 0.7 | 2.1 | 5,200 | 2,200 | 0.4 | 1.7 | 4,500 | 1,900 | 0.25 | 1.35 | 3,400 | 950 | 0.25 | 1.35 | |

| 2080-1400 | 14 | 9,500 | 3,000 | 0.7 | 2.1 | 5,200 | 2,200 | 0.4 | 1.7 | 4,500 | 1,900 | 0.25 | 1.35 | 3,400 | 950 | 0.25 | 1.35 | |

| 2100-1000 | R5 | 10 | 7,500 | 2,500 | 0.8 | 2.5 | 4,300 | 2,000 | 0.5 | 2.1 | 3,750 | 1,750 | 0.3 | 1.7 | 2,800 | 875 | 0.3 | 1.7 |

| 2100-1500 | 15 | 7,500 | 2,500 | 0.8 | 2.5 | 4,300 | 2,000 | 0.5 | 2.1 | 3,750 | 1,750 | 0.3 | 1.7 | 2,800 | 875 | 0.3 | 1.7 | |

| 2100-1800 | 18 | 7,500 | 2,500 | 0.8 | 2.5 | 4,300 | 2,000 | 0.5 | 2.1 | 3,750 | 1,750 | 0.3 | 1.7 | 2,800 | 875 | 0.3 | 1.7 | |

| 2120-1200 | R6 | 12 | 6,200 | 2,000 | 0.9 | 3 | 3,600 | 1,750 | 0.6 | 2.6 | 3,150 | 1,500 | 0.35 | 2 | 2,350 | 750 | 0.35 | 2 |

| 2120-1800 | 18 | 6,200 | 2,000 | 0.9 | 3 | 3,600 | 1,750 | 0.6 | 2.6 | 3,150 | 1,500 | 0.35 | 2 | 2,350 | 750 | 0.35 | 2 | |

| 2120-2200 | 22 | 6,200 | 2,000 | 0.9 | 3 | 3,600 | 1,750 | 0.6 | 2.6 | 3,150 | 1,500 | 0.35 | 2 | 2,350 | 750 | 0.35 | 2 | |

思诚资源为您提供:日本佑能UNION 2刃HARDMAX涂层系列 HSB球刀的采购报价、UNION(佑能)G5ACB0F4D697B1型号参数、规格图片、PDF画册等资料,如您想了解更多关于UNION(佑能)正品品牌的其他球刀资料与产品货期库存、行情价格,就在思诚资源MRO商城。

备注:因厂家会在没有任何提前通知的情况下更改产品包装、产地或者一些附件,本公司不能确保客户收到的货物与思诚资源网站提供的产品图片、产地、附件说明等完全一致。若本网站没有及时更新,敬请谅解!